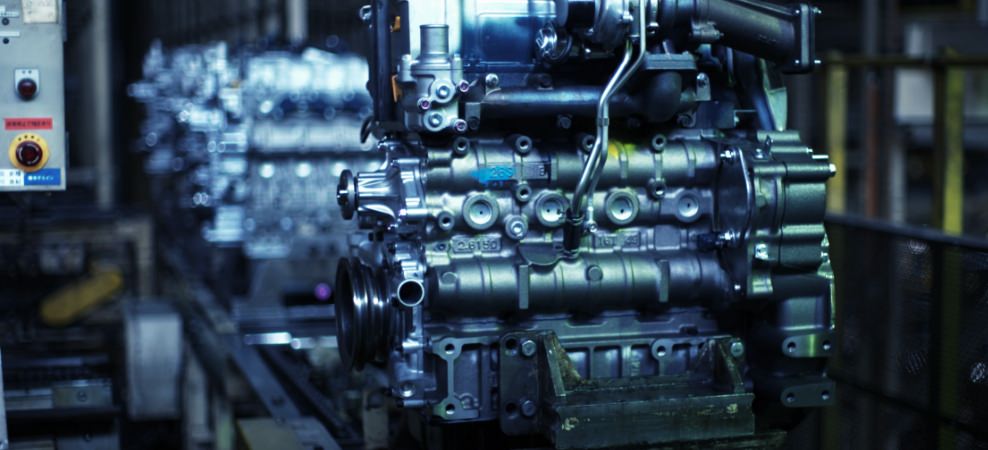

Machining

Machining Key Components is an Important Process for Further Improving Accuracy and Strength

Other major contributors to the "higher output density in more compact bodies" for which Kubota is so highly regarded include mutual adjustment of specially optimized components and high tolerance control via precise machining accuracy.

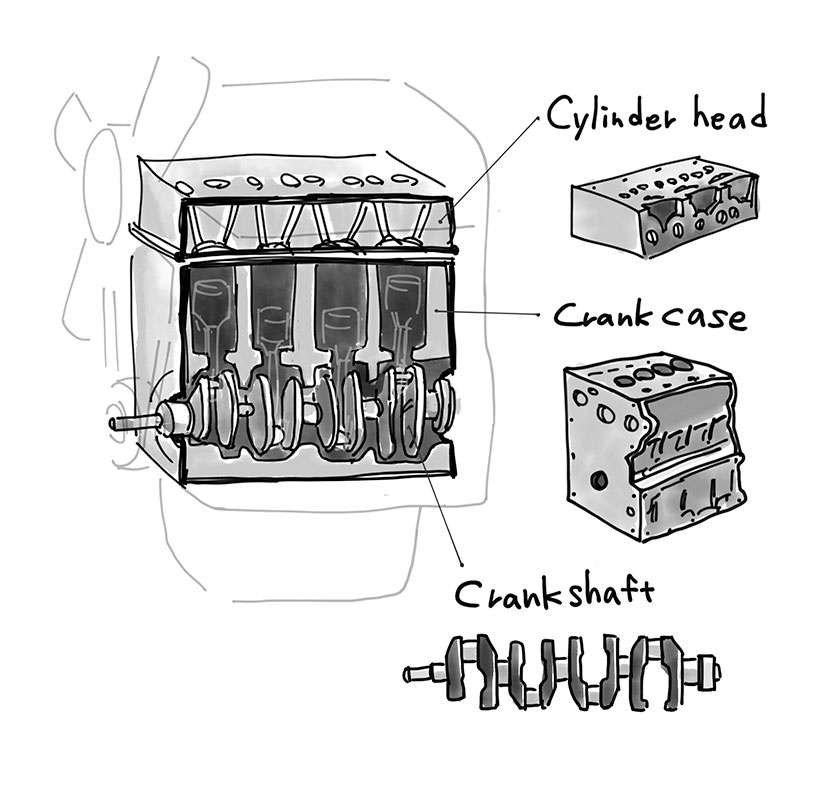

Kubota machines crankshafts, crankcases, cylinder heads, etc. for Kubota engines in-house.

We have determined machining methods based on all conditions, including the selection of machining methods and tools, required surface roughness, accuracy, and expansion rate, etc., and have established stable quality control techniques by making full use of our manufacturing know-how for suppressing variations.

This high accuracy and precise design create many performance improvements and benefits of Kubota Engine such as "low noise," "low vibration," "improved fuel efficiency," "reduction of blue and white smoke," and "durability," which have led to our being highly regarded for "higher output density in more compact bodies."

-

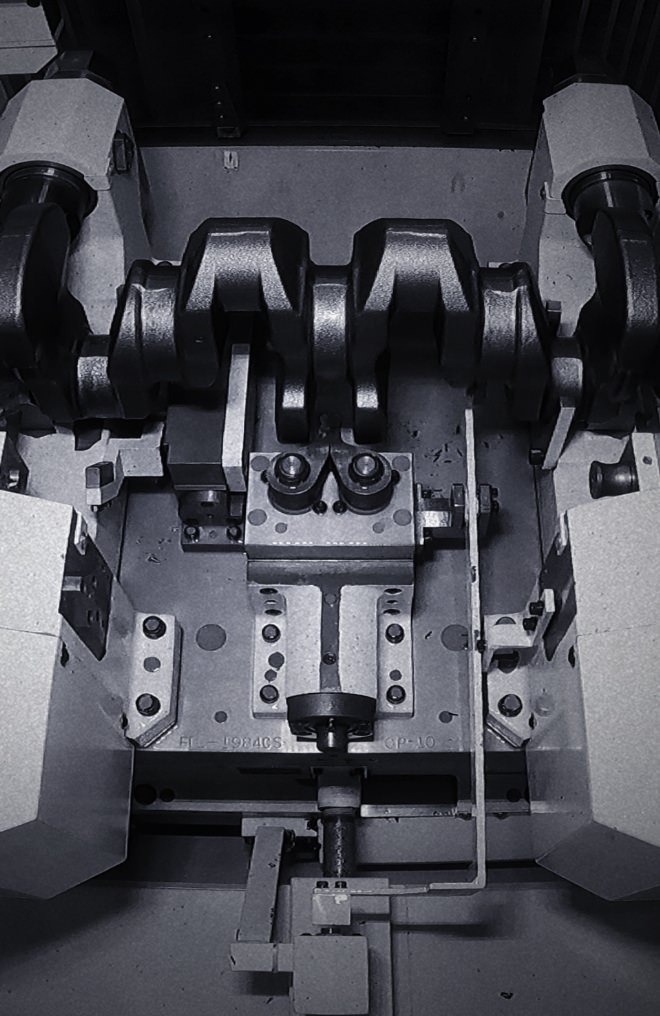

Crankshaft

-

-

Machining

Crankshaft

We use machinery to automate crankshaft machining. We use an automatic transport system to carry crankshafts through machining steps that perform precision operations in stages.

-

Machining

Crankcase

This is the process we use to machine crankshafts, which could be called the hearts of our engines. Vibration and noise countermeasures pose a challenge to achieving the highest possible engine output density, so, to overcome this, and to ensure proper waterways and rigidity, we give our crankcases complicated shapes that make them look as if parts have been ground off. Kubota is able to achieve these complex shapes thanks to our many years of casting experience.

-

Machining

Cylinder head

High precision operations are also required for machining cylinder heads, but since this work is largely standardized, we have introduced automation via robots to handle most of it. This video introduces the processes we use at each of our manufacturing locations.

Crankcase

-

-

-

Machining

Crankshaft

We use machinery to automate crankshaft machining. We use an automatic transport system to carry crankshafts through machining steps that perform precision operations in stages.

-

Machining

Crankcase

This is the process we use to machine crankshafts, which could be called the hearts of our engines. Vibration and noise countermeasures pose a challenge to achieving the highest possible engine output density, so, to overcome this, and to ensure proper waterways and rigidity, we give our crankcases complicated shapes that make them look as if parts have been ground off. Kubota is able to achieve these complex shapes thanks to our many years of casting experience.

-

Machining

Cylinder head

High precision operations are also required for machining cylinder heads, but since this work is largely standardized, we have introduced automation via robots to handle most of it. This video introduces the processes we use at each of our manufacturing locations.

Cylinder head

-

-

Crankshaft -

Crankcase -

Cylinder head

FACTORY QUICK TOUR

View

-

Design

We design engines to deliver optimum performance while meeting the specifications all our customers worldwide require based on their requirements and potential needs. Our extensive installation track record and proven technical expertise backed by verification testing ensure our engines have the durability for any application. We design high quality engines by collaborating with our casting department and incorporating knowledge from our manufacturing department in addition to applying engine development technology. We also have a group of experts developing the products in a wide range of fields such as machinery, electronics, chemistry, and physics.

-

Workshop

The Kubota engine development team makes each engineer responsible for the bulk of development in a given area of engine development. This may also be a characteristic that distinguishes us from other engine manufacturers. Engineers conduct design and research based on information from CAD data, etc. while assembling actual engines themselves at assembly and disassembly areas in our development facilities. We work hard to improve the performance of each engine model by advancing development based on specialized knowledge and detailed data, while carefully assembling engines by hand.

-

Test equipment

We measure exhaust emissions of designed and developed engines in our "Quality Audit Building."

In January 1995, the state of California in the US became the first in the world to enforce the "CARB ULG Exhaust Gas Regulations." To get out ahead of enforcement of these regulations, Kubota was the world's first engine manufacturer to obtain certification in 1993.

Even as emission regulations for industrial engines become more stringent, our development environment has stayed compliant with regulations in all regions of the world.

-

Chassis dynamometer

We use a piece of equipment called a "chassis dynamometer" that mounts engines on actual applications, puts the applications on chassis rollers, and then places loads on engines that mimic loads during real driving scenarios. We check engine loads and performance based on actual operating conditions and by using wind tunnel equipment to improve the quality of engines optimized for applications.

-

Foundry-core automatic coating machine

We automatically paint the "foundry cores" that become crankcase molds to stabilize their quality.

-

Foundry-core automatic assembly line

We assemble these "foundry core" crankcase molds automatically. We stabilize the dimensions of complex structures so we can mass produce high quality crankcases.

-

Air impact molding machine

We use the air impact method to form the casting sand of foundry cores at uniform pressures. By using net shaping technique, we achieve thin walled products with high dimensional accuracy. We visually confirm that molds do not break when molten metal is poured in.

-

Core setting machine

We use automatic core setting devices to improve the dimensional accuracy of our crankcases.

-

Automated pouring machine

This is a pouring operation that pours metal into molds in a hot liquid state.

Kubota uses triangular ladles with shapes suitable for automatic pouring to save labor in pouring operations.

-

Product picking line (manipulator)

This is an operation that flushes molds to remove molded castings. Kubota uses a heavy machine called a manipulator to free workers from heavy work and heat.

-

Product boxing and automated warehousing (SA storage)

Our unique SA box method is a self-annealing method with excellent moisture retention properties that cools slowly using residual heat from products. This method cools molds from top to bottom in 8 hours.

It also saves energy and shortens lead times.

-

Automatic casting burr removers

Molten metal that flows out through gaps between molds solidifies into thin extraneous bulges called casting burrs.

We have introduced "automatic casting burr removers" to remove these burrs. They automatically find rough spots on products and clean casting burrs from product surfaces.

-

Shot blasting

After removing casting burrs, we give products their final finishes by shot blasting them with small iron ball-shaped projectiles.

-

Coating (first time)

Our LFP line is used as the production line when casting crankcases with more complex shapes.

We apply refractory material to extruded polystyrene foam models with the same shape as the products.

-

Drying (batch furnace)

We dry the models coated in refractory material in a batch furnace.

-

Coating (second time)

We apply more refractory material to the models after they have been dried in the batch furnace.

-

Drying (continuous furnace)

We use a continuous furnace to dry models after their second coating.

-

Molding and pouring

We shape the models that have finished drying in the continuous furnace into molds and pour molten metal directly into the shaped molds.

-

Shot blasting

After pouring the molten metal, we give the molded products their final finish by shot blasting them with small iron ball-shaped projectiles.

-

Inspection (appearance, omissions, dimensions)

After shot blasting, we inspect products for appearance, omissions, and dimensions.

-

Crankshaft

We use machinery to automate crankshaft machining. We use an automatic transport system to carry crankshafts through machining steps that perform precision operations in stages.

-

Crankcase

This is the process we use to machine crankshafts, which could be called the hearts of our engines. Vibration and noise countermeasures pose a challenge to achieving the highest possible engine output density, so, to overcome this, and to ensure proper waterways and rigidity, we give our crankcases complicated shapes that make them look as if parts have been ground off. Kubota is able to achieve these complex shapes thanks to our many years of casting experience.

-

Cylinder head

High precision operations are also required for machining cylinder heads, but since this work is largely standardized, we have introduced automation via robots to handle most of it. This video introduces the processes we use at each of our manufacturing locations.

-

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Leak test

After assembly, we place engines in water to check for leaks.

-

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

-

Rigging

This is a line that outfits engines of various sizes and weights simultaneously. To reduce physical burdens on workers, the line can suspend heavy engines and align engine assembly heights so workers can move them more easily.

-

Painting

We paint our assembled engines. Engines are automatically transported to paint booths where robots and workers paint them with a variety of paints.

-

Operation inspection

We perform operational inspections by filling all assembled engines with fuel and starting them.

Our system monitors the different performance requirements of all engines, and inspects them for vibration, sound, fuel injection quantity, power output, and so on. This is how we ensure the performance and quality of our engines.

-

Sampling inspection

We thoroughly check exhaust gas values for randomly pulled engines.

We take precise measurements to determine whether the engines meet the standards of each region of the world.

-

DPF cleaning equipment

Diesel Particulate Filters (DPFs) are exhaust gas after-treatment devices that filter and reduce particulate matter (PM) in diesel engine exhaust gases. We also have equipment that measures whether DPFs are functioning properly, and that can inspect them when needed.

-

Pre-shipment inspection

We conduct external appearance sampling inspections as pre-shipping inspections.

-

Returnable pallet

As part of our environmental efforts, the pallets we use for shipping are returnable pallets that can be used many times after delivery.

-

Eco-friendly packaging

We have abolished excessive packaging, and pack products in a manner that saves resources.

-

Shipping

We place packaged engines on returnable pallets, and load the pallets into containers.

From there, we deliver Kubota engines to customers around the world.

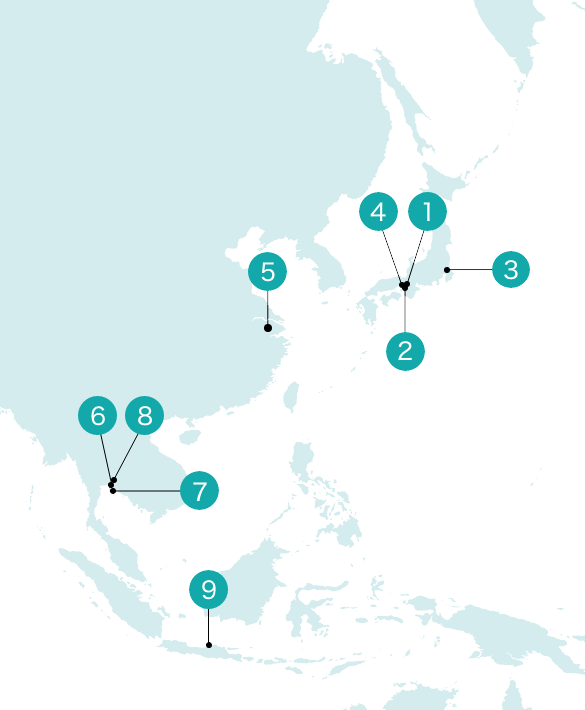

Kubota Engine Factory Network

Japan

-

Okajima Business Center

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

-

Sakai Plant

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

-

Tsukuba Plant

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

-

Sakai Rinkai Plant

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

China

-

Kubota Engine (WUXI) Co., Ltd.

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

Thailand

-

SIAM KUBOTA Corporation Co.,Ltd.

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

-

SIAM KUBOTA Metal Technology Co., Ltd.

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

-

KUBOTA Engine (Thailand) Co., Ltd.

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-

Indonesia

-

P.T. Kubota Indonesia

-

Okajima Business Center

7-1-22 Minami-okajima, Taisho-ku, Osaka, 551-0021, Japan

Manufacturing industrial cast iron products,drainage pipes and other cast iron products

-

Sakai Plant

64 Ishizu-kitamachi, Sakai-shi, Osaka, 590-0823, Japan

Manufacturing engines, tractors and small-size construction machinery, etc.

-

Tsukuba Plant

10 Sakano-Shinden, Tsukuba-Mirai-shi, Ibaraki, 300-2402, Japan

Manufacturing engines and tractors, etc.

-

Sakai Rinkai Plant

3-8 Chikko-shinmachi, Nishi-ku, Sakai-shi, Osaka, 592-8331, Japan

Research and development of engines, acquiring certification and responding to audits for emission regulations, and manufacturing engines, agricultural machinery, and compact construction machinery, etc.

-

Kubota Engine (WUXI) Co., Ltd.

20, Xinhua Road, Xinwu District, Wuxi, Jiangsu, 214028, China

Manufacturing of vertical type diesel engines

-

SIAM KUBOTA Corporation Co.,Ltd.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlongnueng, Amphur Khlongluang, Pathumthani 12120, Thailand

Manufacturing and sales of tractors, combine harvesters, horizontal diesel engines and power tillers, and sales of construction machinery

-

SIAM KUBOTA Metal Technology Co., Ltd.

359 Moo 3, Khao Hin Son, Phanom Sarakarm, Chachoengsao 24120, Thailand

Manufacturing of casting components for engines and tractors

-

KUBOTA Engine (Thailand) Co., Ltd.

360 Moo3, T.Khao Hin Son, Phanom Sarakarm, Chachoangsao 24120, Thailand

Manufacturing of vertical type diesel engines

-

P.T. Kubota Indonesia

Taman Industri Bukit Semarang Baru (BSB) Blok D.1 Kav.8, Kel. Jatibarang - Kec.Mijen, Semarang, Indonesia

Manufacturing and sales of small diesel engines

-