Gonshiro Goes His Own Way

Born in Ohama Village on Innoshima Island (present-day Ohama-cho, Innoshima, Onomichi City, Hiroshima Prefecture) in 1870, Gonshiro Ohde came to Osaka at the age of 14, and saved money while training at a foundry. He rented a corner of a tenement house in February 1890 and founded Ohde Casting at the young age of 19.

This is the beginning of Kubota's history, which has spanned more than 130 years. In the early days, Gonshiro made weights and components for scales, but gradually his casting gained a reputation for quality and accuracy, and he began to receive orders for the casting of machine parts and daily necessities such as pots and kettles, which are more technically difficult. In 1894, the name of Ohde Casting was changed to Ohde Foundry.

Demonstrating Skill as a Casting Manufacturer

Innovating the production of iron pipes for waterworks to become a leader in the industry

The advent of modern lifestyles led to the spread of infectious diseases such as cholera, which in turn necessitated the development of water supply systems in many areas.

At that time, iron pipes for waterworks in Japan had to be imported. Many companies attempted to produce them domestically, but failed due to a lack of technical skill.

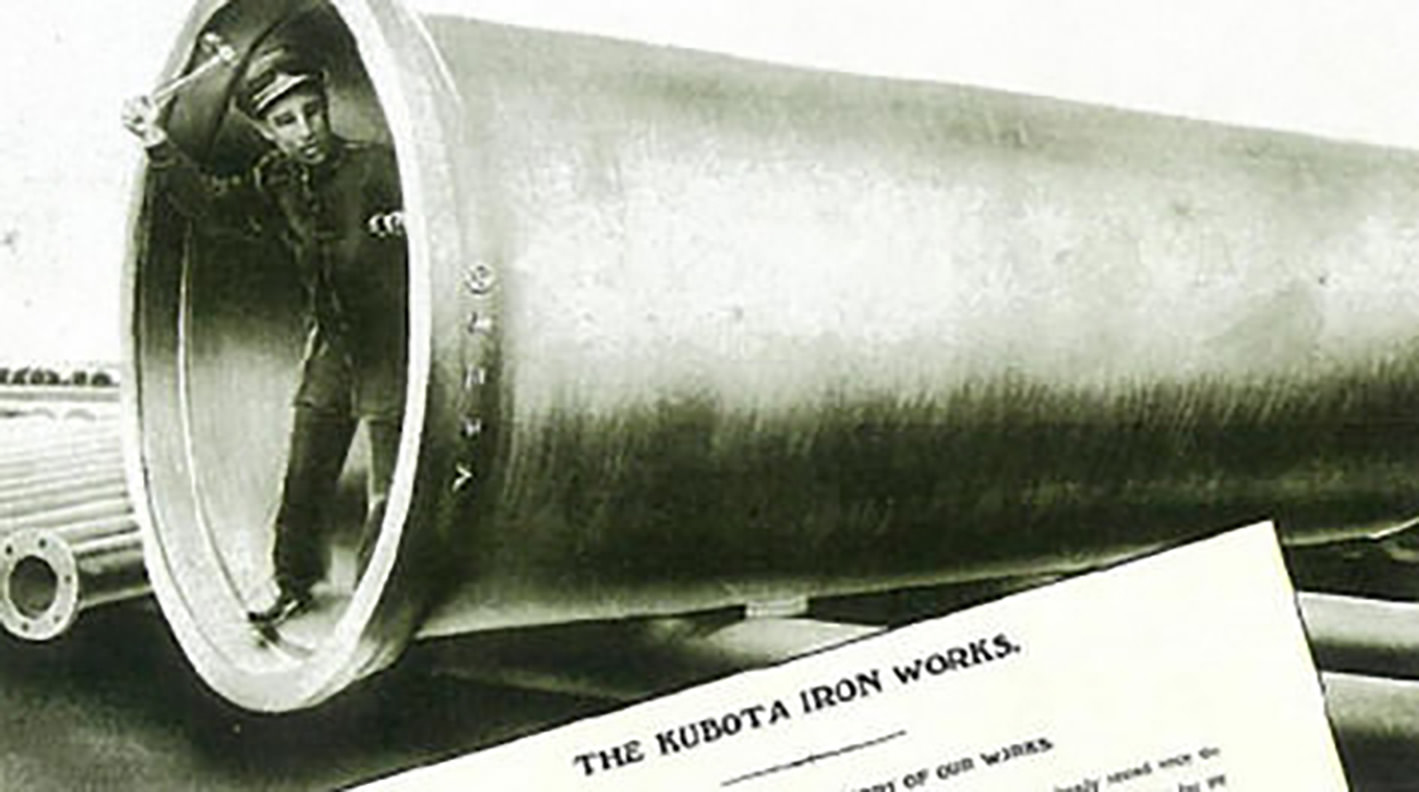

To benefit Japan, Gonshiro Ohde also started manufacturing iron pipes, but he faced more difficulties than expected. However, his efforts finally bore fruit in 1897 when he developed the "joint-type casting method."

In that year, the company name was changed to Kubota Iron Works. The history of water pipes in Japan is intertwined with the history of Kubota.

Later, in 1900, the "vertical round blow casting method" was developed, and in 1904, "vertical blow rotary type casting equipment" was developed, after which the mass production of iron pipes began.

In 1917, the Amagasaki Plant (now the Hanshin Plant) was established, and the facilities and personnel of the iron pipe division were transferred to there from the main office.

Cutting Edge Casting Technology

Okajima Plant

Established

In response to rapid growth, the main plant became a dedicated plant for the machinery division, while the iron pipe division was transferred to the Amagasaki Plant. Also, the casting division, which had facilities scattered throughout Japan, was consolidated into the Okajima Plant, which was built in Minami Okajima-cho, Nishi-ku, Osaka City (currently Taisho-ku, Osaka City). These changes clarified the bases for the three divisions: casting, iron pipes and machinery.

Employees were sent to seek out opportunities in other Asian markets, where imports of iron pipes from Europe had stopped. From those efforts, 2,000 tons of iron pipes were exported to Java (now Indonesia) for the first time in this year.

Learning from Setbacks

in the Automotive Business

Establishment of Jitsuyo Jidosha Co., Ltd.

After Kubota Ironworks succeeded in mass-producing iron pipes for waterworks, it embarked to diversify its businesses into fields including the manufacture of machine tools and machinery for the manufacture of steel.

At that time, Kubota spread its attention across all kinds of businesses and implemented various initiatives. Of these, one of the most unique businesses was that of automobile manufacturing.

In around 1920, the middle of the Taisho era, automobiles began taking the place of rickshaws. However, imported cars were expensive to purchase and maintain, and were not suitable for the narrow roads of Japan.

For that reason, Jitsuyo Jidosha Co., Ltd., was established with the aim of manufacturing practical automobiles appropriate for the Japanese market.

The company purchased a patent from an American who was visiting Japan and began manufacturing the "Gorham-style three-wheeled vehicle". However, business struggled when a large number of American automobiles were imported following the Great Kanto Earthquake, after which the company merged with DAT Motorcar Company of Tokyo.

In 1931, the company developed a water-cooled, four-cylinder, 500-cc compact automobile prototype, and the following year, it completed a non-stop test run between Osaka and Tokyo, and marketed the vehicle under the name Datson.

It is believed that the characteristic technologies of Kubota Engine, such as the miniaturization of engines for small cars, precision casting technology, and high durability, were accumulated here.

However, the company was unable to overcome competition from foreign cars and its shares in the company were transferred to Tobata Foundry Co. After that, the name Datson was changed to Datsun, and the famous domestic brand of cars was born.

Although Kubota Iron Works had effectively withdrawn from the automobile manufacturing business, had it not been for the efforts put into the automobile business at that time, Kubota Engine may have never gotten off the ground.

1

The Eve of Foundation

-

Gonshiro Goes His Own Way

-

Demonstrating Skill as a Casting Manufacturer

-

Cutting Edge Casting Technology

Okajima Plant Established -

Learning from Setbacks

in the Automotive Business