Beginnings as a Source

of Power for Agriculture

Post-war drought in Japan leads to the rapid spread of Kubota agricultural oil engines

It was in 1915 that the first oil engine was introduced in Japan for agricultural use. This device is believed to have been imported from the United States.

American-made engines were gradually used by Japanese farmers as power sources for threshing, hulling, and pumping water.

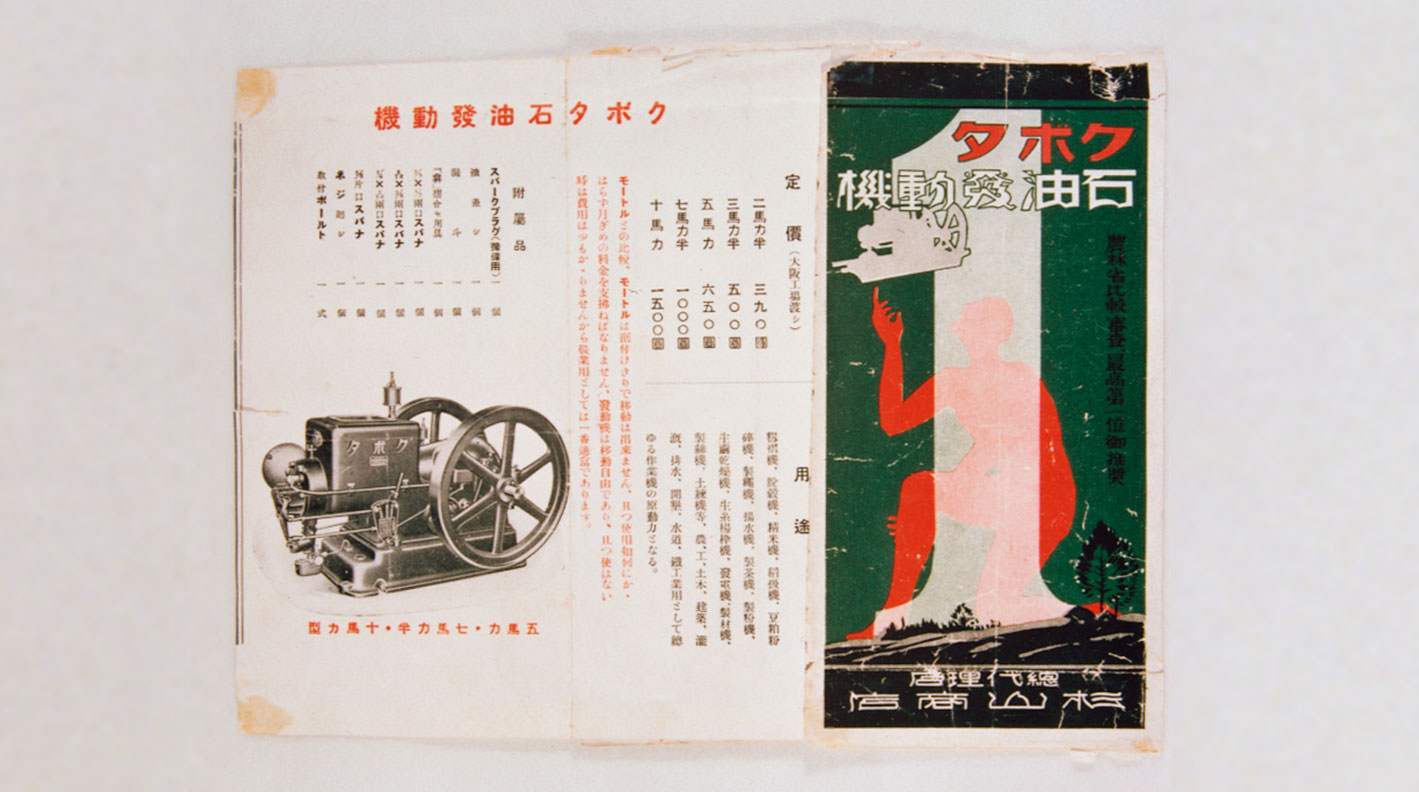

Kubota's production of agricultural oil engines dates back to 1922.

At that time, a severe drought had hit western Japan, increasing demand for both water pumps and oil engines, contributing to their popularization.

As the economy worsened with the end of the war, Kubota searched for a new strength to serve as an alternative to its main business from the machinery division, at which time it was approached by Sugiyama Shoten, a pump dealer and distributor of imported engines, to begin manufacturing engines in Japan.

Sudden rise to becoming a core player in the industry

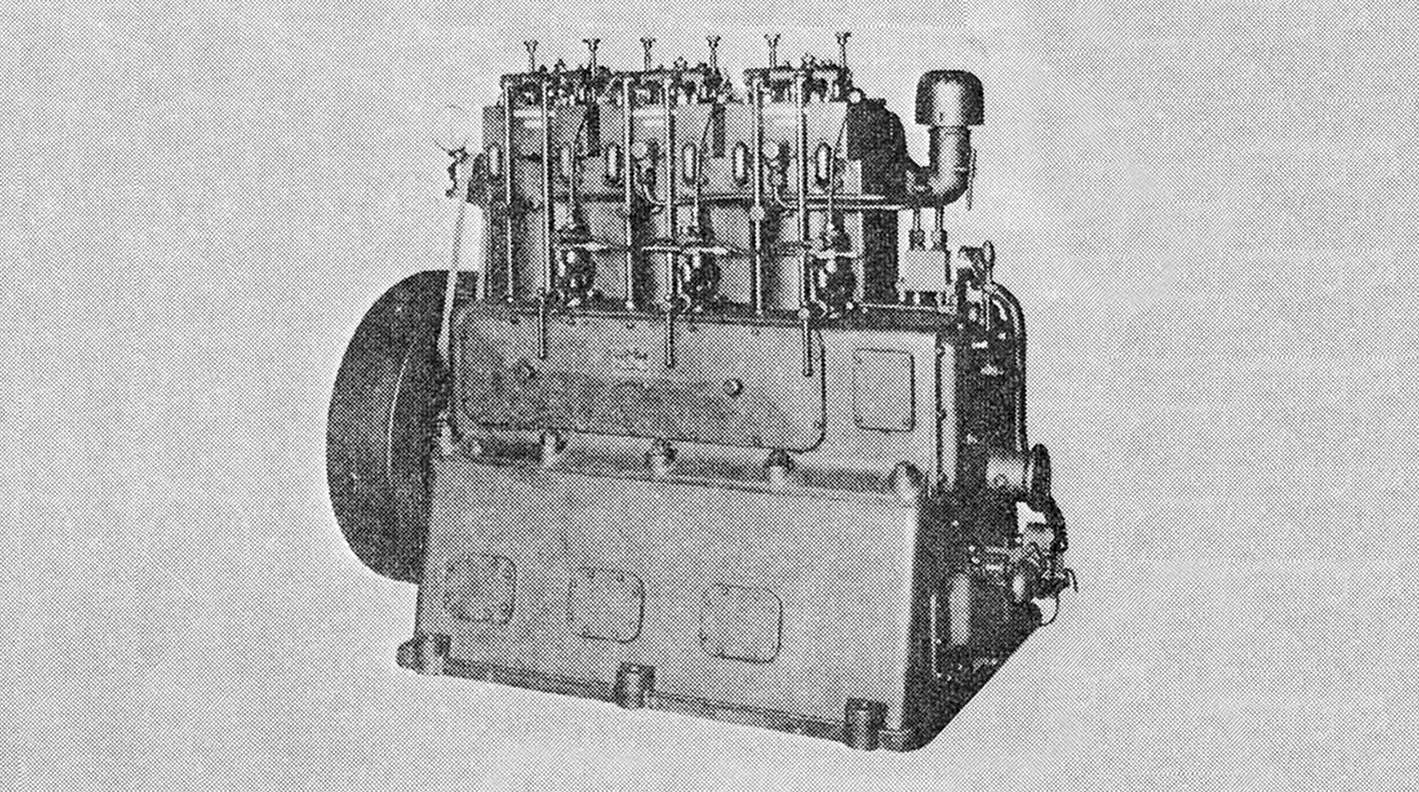

Utilizing advanced casting technology, the company had developed since its founding, as well as the production facilities and manufacturing technology of the machinery division, Kubota began to develop engines in a corner of the warehouse of its main plant.

In 1923, the company launched the three-horsepower Type-A Agricultural Engine, designed to be a domestically manufactured engine with low noise and a compact size. This engine witnessed steady sales as a power source for irrigation pumps and rice hullers, resulting in more models being offered.

In 1927, the company developed an engine for fishing boats that used magnetos and plugs manufactured by Bosch of Germany. The company continued to grow steadily, expanding its sales channels.

Kubota's engines, which used technology cultivated in the water pipe casting industry, were highly acclaimed at exhibitions and in comparative performance tests, enabling Kubota to quickly become a key player in the industry despite its late entry.

Cooling Channels

Demonstrate Kubota's

Casting

Technology

Kubota's cooling channel casting technology is one technology that enables Kubota Engine to develop engines that are compact yet provide high output, two characteristics that are normally contradictory.

Water channels that cover and cool the entire cylinder, where high heat is generated, are usually created by drilling. This is performed using a method that involves machining the metal, which results in variations in quality.

To alleviate these variations, Kubota succeeded in creating water channels from the beginning using a casting process. By creating optimal water channels by casting instead of machining the metal, the engine is made extremely robust and with high cooling effects, resulting in a compact and high-output engine.

The cooling channel, which was developed from the design stage in cooperation with the casting manufacturing division, is one of technology that goes back to the time of Kubota's founding, when casting was the origin of its business.

2

Why Did Kubota Start Making Engines?

-

Beginnings as a Source

of Power for Agriculture -

Cooling Channels

Demonstrate Kubota's

Casting Technology