Assembly

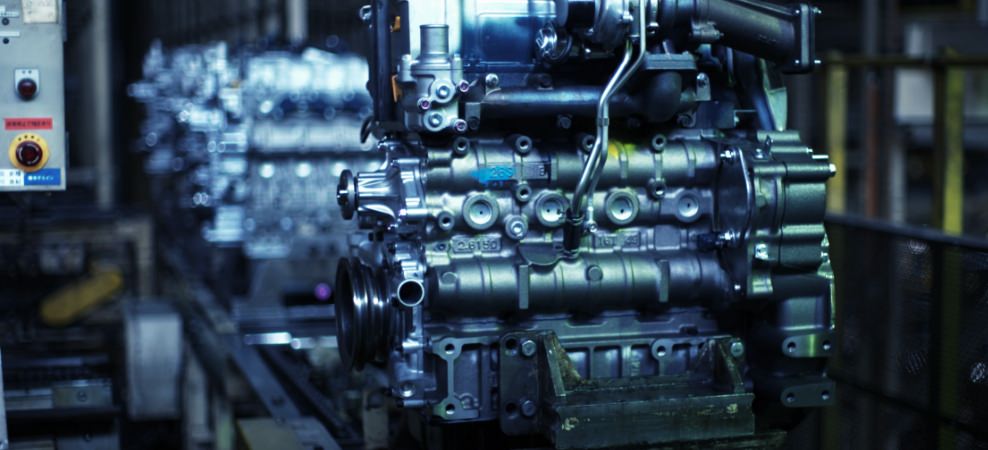

A Unique Assembly Production System that Assembles Engines with Different Specifications in a Single Line

Engines with the same specifications are typically produced on the same assembly line.

We have designed the Kubota engine assembly line based on a different concept.

This concept calls for assembling multiple engines with different specifications on a single line.

Kubota Engine routinely produces 2,000 or more engines simultaneously, while also responding quickly to fluctuations in production volumes and changes in specifications as requested by customers.

-

Production plan creation

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Part selection

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Assembly

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

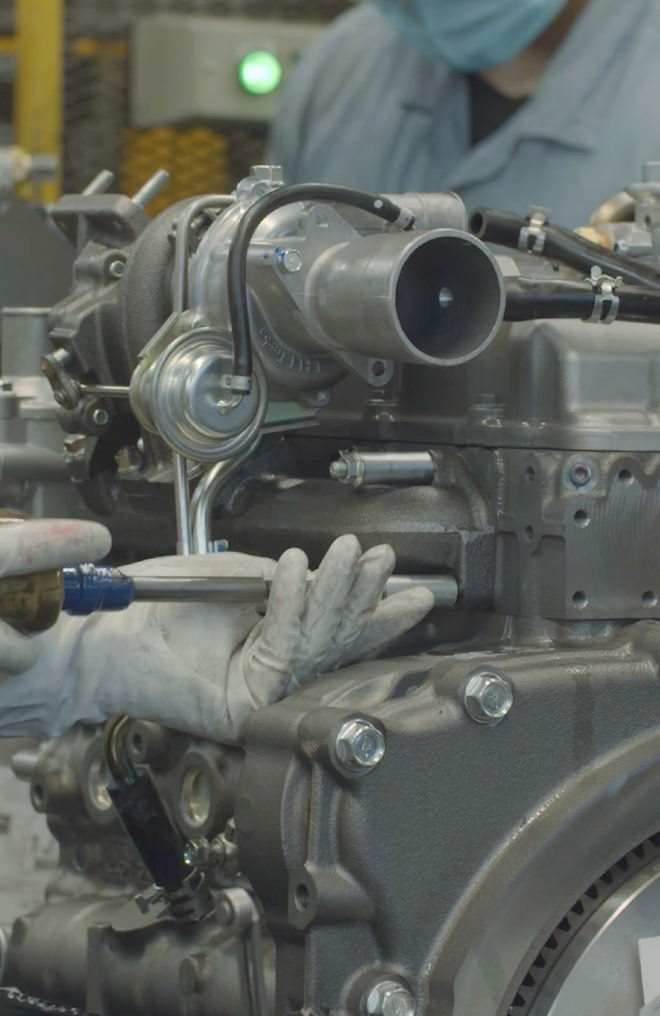

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Cylinder head assembly

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Defect prevention device

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

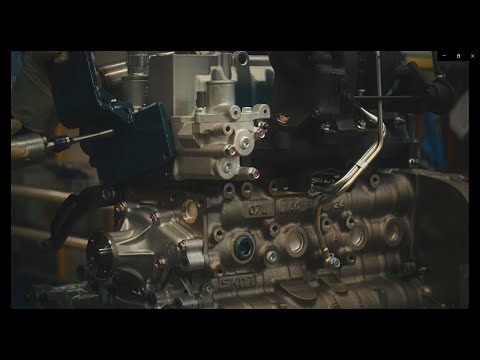

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Nutrunner

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Torque check

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Traceability

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

Leak test

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

DPF

-

-

-

Assembly

Production plan creation

We create an assembly order table, list the components required for each assembly line, and create a production plan.

This order table allows us to manage the complex steps required to assemble over 2,000 engine models.

-

Assembly

Part selection

We use barcodes to manage the assembly order table. When barcodes are read in engine component pick-up areas, lights light up in the locations where the components required for each engine are kept so workers can go pick them up. We also arrange Automated Guided Vehicles (AGVs) in locations where they can be used to automatically carry components to the line.

-

Assembly

Assembly

The line displays assembly instructions for engines with different specifications on screens, thus enabling workers to accurately assemble different engines one at a time.

-

Assembly

Cylinder head assembly

This shows our automated cylinder head assembly process.

-

Assembly

Defect prevention device

Fool-proofing (poka-yoke) is a way of thinking and a method for creating a state where mistakes do not occur.

We carefully designed the Kubota engine assembly line, which produces a wide range of products in small quantities, to prevent assembly errors. The correct components must be attached to engines carried along the line at each specific step before the engines can advance to the next step. For example, in our Sakai Plant, we have installed fool-proofing devices in approximately 200 locations and introduced mechanisms to ensure that workers are only able to use the correct components and tools.

-

Assembly

Nutrunner

We have implemented nut runners in the assembly process that tighten all joints with nuts at once.

This video shows the joining of crankshafts to cylinder heads.

-

Assembly

Torque check

We check torque values on the line during the assembly process. Each and every engine is carefully inspected to see whether it has the required torque values. We also check the tools workers are using.

-

Assembly

Traceability

To manage engine performance, exhaust gas response, and safety, we have set regulations for each factory and carry out traceability according to strict standards for things like nut runner tightening record traceability and injection timing traceability.

-

Assembly

Leak test

After assembly, we place engines in water to check for leaks.

-

Assembly

DPF

At Kubota, we also manufacture DPFs in-house, which are very important components in emission regulations around the world. At our Sakai Rinkai factory, workers assemble components while riding on Automated Guided Vehicles (AGVs).

-

Assembly

IPU

Injection Pump Units (IPUs) are components that send fuel into diesel engine combustion chambers at high pressures. Kubota has also created an independent line for producing these components in-house for mounting in its V3 Series of Kubota engines.

IPU

-

Kubota INNOVATIVE METHOD

Kubota's uniquely consistent

production system,

featuring innovations

unlike any in the world