From Gasoline to Diesel

In Japan, fishing boats equipped with engines began to appear in the 1906, the late Meiji period, and from around 1915, the power and size of fishing boats was rapidly increasing. After that, a transition was made from using motorboats as fishing boats to using diesel ships for reasons related to fuel and operational performance.

Focusing on this transition to diesel, Kubota began the development of marine diesel engines around 1927, utilizing its oil engine manufacturing technology, as well as its discontinued steam engine technology and experience. After this, the company entered the field of land diesel engines used to power water pumps and sawmills, receiving praise from the market.

Diesel engines are widely used for ‘industrial engines,’ which are typically used in agricultural machinery, construction machinery, electrical machinery such as generators, and industrial machinery.

In particular, engines for agricultural machinery are operated under intense load fluctuations. Often used in continuous operation under high loads, at low engine speeds and high torques, the entire machine must operate under severe shaking and vibration, in scorching sun, in rainfall, in muddy water, and in extremely dusty locations.

Furthermore, they are often left outdoors and used without any special protective coverings, and the work is not constant throughout the year and the duration of use is not consistent.

For these reasons, they must be durable, waterproof, and dustproof, be capable of inclined operation, have good startability, and be easy to service and maintain. To fulfill these requirements, it became necessary to use diesel engines instead of gasoline engines.

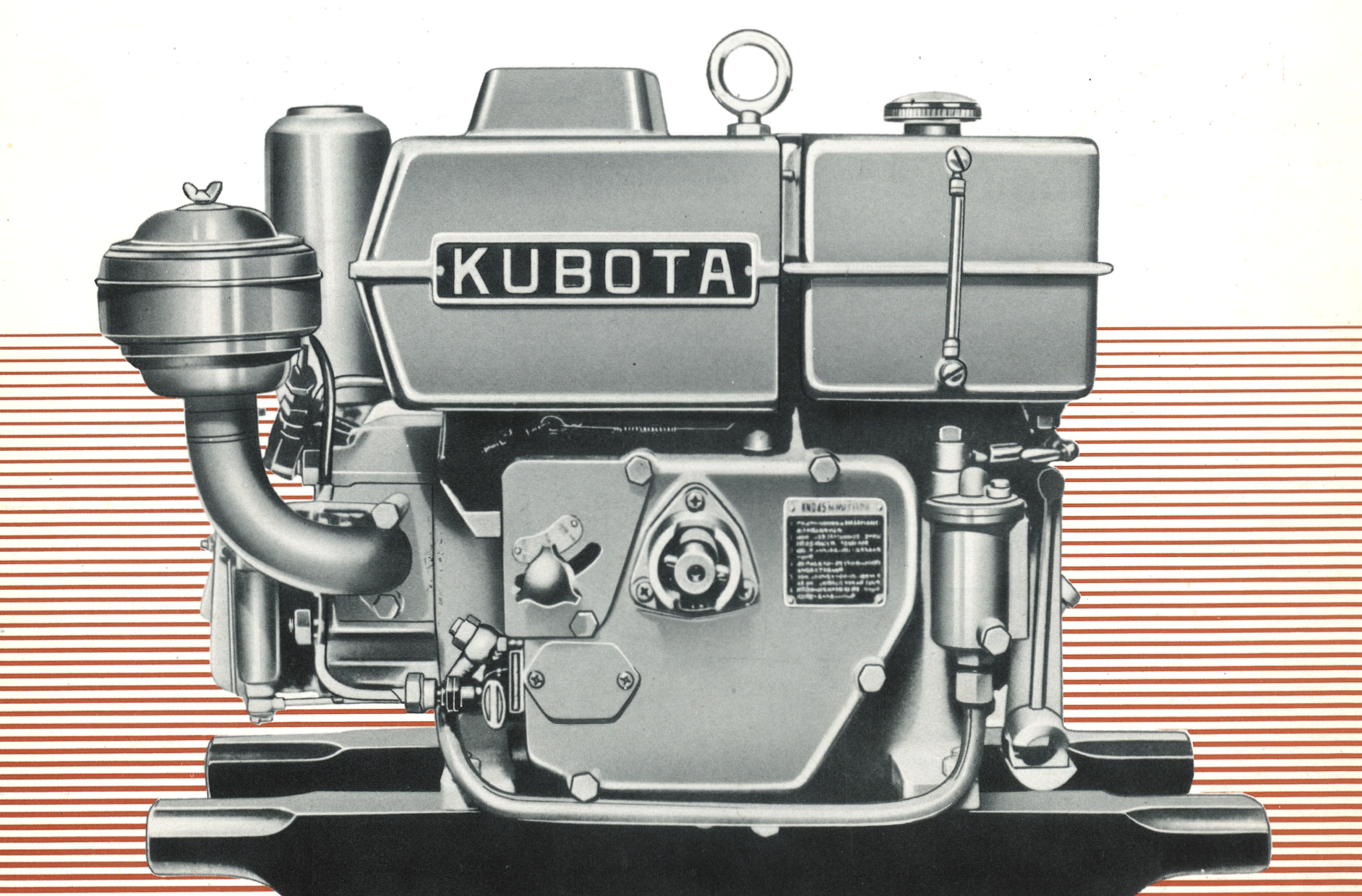

The Horizontal Diesel Engine

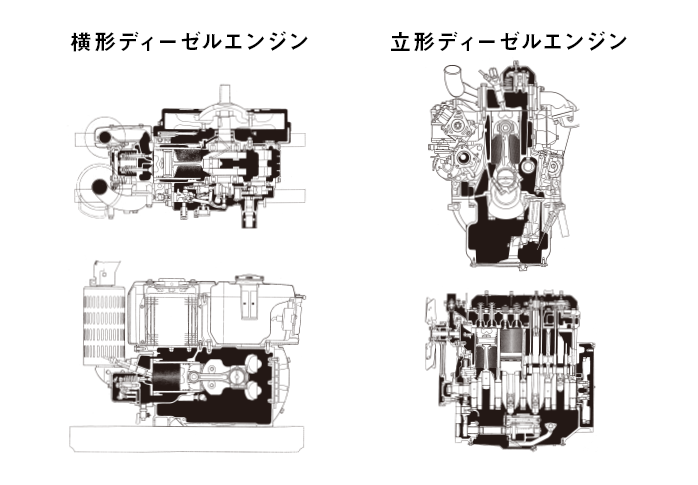

Based on the cylinder arrangement, engines are referred to as vertical, horizontal, inline, V-type, horizontally opposed type, or inline/slanted.

Horizontal diesel engines are diesel engines with the cylinders in a horizontal arrangement, while vertical diesel engines are diesel engines with the cylinders in a vertical arrangement.

Kubota's horizontal diesel engines are commonly used as engines for walking cultivators.

Origin and Characteristics of the Kubota Horizontal Diesel Engine

Kubota, which began manufacturing oil engines in 1922, acquired rights from the German company Bosch to produce seven types of diesel engines ranging from 6 to 75 horsepower in 1930. The company installed technology from Bosch in Germany at its Funade-cho plant and began production of Acro Engines (Air Cell Engines). The company expanded into the field of land diesel engines for water pumps and sawmills.

The Acro Engine is a combustion chamber system (a type of air cell type combustion chamber), and Kubota engines supposedly had an air chamber in the piston head.

In 1950, Kubota began manufacturing H-type water-cooled horizontal diesel engines (HD5, HD8 and HD10). Three years later, in 1953, it received the Minister's Award for Comparative Performance Testing from the Ministry of International Trade and Industry of Japan, and continued to be highly praised.

Although oil engines were at the height of their popularity for use in tillers during the post-war reconstruction period, diesel engines with high torque (toughness) at low speeds, good fuel efficiency and durability enjoyed deep-rooted popularity with professionals, resulting in an expanded market.

Tillers were transitioning from being used in fields to being used in rice paddies, and it is said that horizontal diesel engines, which closely resemble oil engines in their appearance, were the ideal engine for use in rice paddy tillers that require low-speed, high-torque operation.

The History of Kubota's Horizontal Diesel Engine

This is a summary of the history of the major horizontal diesel engines.

1950: Production of water-cooled horizontal diesel engines

begins (HD5, HD8, HD10)

1953: Received award from the Minister of International Trade

and Industry for the general-purpose KND8-Type

(general-purpose small internal combustion engine)

1958: KNDR5 radiator-type horizontal diesel engine developed,

VA VC 2-cycle horizontal diesel engine developed

1976: E-type series horizontal diesel engine developed (the

birth of Kubota's unique TVCS combustion chamber)

1984: EA/RK Series water-cooled horizontal diesel engines

developed

1997: RD Series water-cooled horizontal diesel engine

developed

2001: RT Series water-cooled horizontal diesel engine

developed

2018: ZT Series water-cooled horizontal diesel engine

developed

Features of Kubota's Horizontal Diesel Engine

Since being first produced and up until now, Kubota's horizontal diesel engines have undergone repeated developments and given many features. Let us introduce some of these. Although this includes technology that is taken for granted now, it can be said that the dedication of the engineers of the time shaped the Kubota horizontal diesel engine of today.

1. Compact and Lightweight, Low Fuel Consumption (High

Power Density)

Obliquely cut connecting rod, shallow plate re-entrant cavity,

thin piston ring, stroke increase in the same size with low

profile pistons, aluminum die-cast crankcase

2. High Output, High Torque (Engine Stall Resistant), Low

Exhaust Gas (Emissions Regulation Compliant)

Low-emissions TVCS combustion chamber, swirl port for compact

DI, octagonal cavity, double governor lever with integrated

torque spring and non-contact idle spring to maintain high

torque during half throttle

3. Improved Durability

Main bearing 2 has been rollerized, four thin piston

rings, etc.

4. Ease of Operability

TVCS for low temperature startability, direct injection

below 0.4 L for easy hand-start, double governor spring for

improved acceleration response,

AC regulator for low-speed, high-illuminance

headlights,

LED lamps and left/right blinkers

Automatic air-bleeding fuel filter

5. Improved Cooling Performance (Resistant to

Overheating)

Pressurized box-shaped radiator

6. Low Noise, Low Vibration

Dual axis balancer, upper notch injection pump (slow

retard)

7. Advanced Exterior Design

Boltless exterior, waterproof resin headlights and spoiler

Agricultural Conditions in South-East Asia

In Japan, the transition to large-scale agricultural machinery began in the 1970s, with demand shifting from walking cultivators to tractors. When it comes to engines for tractors, it is difficult to make a multi-cylinder, horizontal diesel engine, there are vibration issues, and the shape of the engine is not suitable.

In addition, with the increasing scale of agriculture and industry, there was a gradual need for more horsepower, which led to greater emphasis on the development of vertical diesel engines, rather than horizontal ones.

However, later, from the 1990s onward, there was increasing demand for walking cultivators in Indonesia, Thailand, and other Southeast Asian countries. These demanded the performance of the compact, high-output horizontal diesel engines that Kubota had been developing over the years, and walking cultivators equipped with horizontal diesel engines became an explosive success.

Kubota's horizontal diesel engines were extremely well received, primarily in Southeast Asia, and in 1997 there was a tiller craze in Thailand, where 190,000 units were shipped. In 2013, 100,000 units were shipped in Indonesia; and in 2016, 100,000 units were shipped in Cambodia.

The reason for this high praise can be said to have been due to the agricultural conditions in Southeast Asia.

For one thing, users in Southeast Asia do not run their engines at full throttle. It is said that this is because they want to avoid break downs, so they prefer engines that can produce high power even at half throttle.

Furthermore, in countries such as Indonesia, there are many terraced fields and terraced rice paddies, resulting in a lot of up-and-down movement. Therefore, Kubota developed a new governor mechanism and made improvements so that high torque is generated even when idling. We developed an engine that can move easily around terraced fields and terraced rice paddies even when idling.

Also, in addition to this development, the external design was improved. As the horizontal diesel engine is part of the tiller's design, adopting a design that is not only attractive but also does not break down due to vibration contributed to its success.

Kubota's engineers traveled to various countries, researched the agricultural conditions, listened to feedback from actual farmers, and generously incorporated their latent needs into the horizontal diesel engine's development, which led to the engine's high praise for functionality and user-friendliness.

Contributed to early emission regulations compliance! The Reason Kubota’s Unique TVCS Combustion Chamber was Developed

Kubota was the first engine manufacturer in the world to meet the California Air Resources Board regulations (CARB) in the United States in 1995. We have always been ahead of our competitors in our compliance with subsequent regulations in the United States (EPA), as well as in Europe and Japan.

Behind Kubota being the first company in the world to meet emissions regulations was the TVCS (Three Vortex Combustion System), a proprietary combustion chamber developed by Kubota.

Actually, the TVCS combustion chamber was originally designed and developed for starting horizontal diesel engines.

A problem with horizontal diesel engines is the difficulty in starting the engine with a hand-start if the engine is not self-started when working in cold regions. For this reason, the development team developed a unique combustion chamber that would allow the engine to start even in an environment with a temperature of 0°C (32°F). They named it the "TVCS combustion chamber."

Introduction of this TVCS combustion chamber made it possible to hand-start the engine even when the external temperature was 0°C (32°F).

Furthermore, improvement in fuel economy performance due to this TVCS combustion chamber resulted in better emissions performance. It was confirmed to meet the target figures set by the aforementioned California Air Resources Board (CARB) in the United States.

In other words, the TVCS combustion chamber, created to advance the horizontal diesel engine, also functioned effectively to help Kubota engines, including the vertical diesel engine, comply with environmental regulations.

Also, it was believed at the time to be difficult to cast a widened injection port like that of the TVCS. We believe this is another achievement of Kubota's commitment to precision casting, made possible by the company's advanced casting technology.

The TVCS was improved, becoming the New TVCS, and then the E-TVCS was developed and introduced into many Kubota engines. Currently, in 2022, the latest version of TVCR is being developed with electronic control.

One might say that it is just a coincidence that the combustion chamber created for fuel economy and startability also resulted in a system that is compliant with emission regulations. However, one could also say that it makes perfect sense that the efforts of the horizontal diesel engine development team, who have always been sincerely committed to user-friendliness, led to such an outcome.

Aiming for an Update at the Same Size

The most significant characteristics of Kubota's horizontal diesel engines are said to be their light weight and power.

What innovations were made to achieve this "high output in a compact size?"

In vertical diesel engines, to increase power, it is common to increase the stroke of the piston, which increases the piston travel (stroke). In addition to this stroke increase, efforts were also made to increase the bore of the horizontal diesel engine to increase the diameter (bore) of the piston.

Combined with a stroke increase, the increased piston diameter

of Kubota's RT series, which has been widened to the utmost

limit (from 94 mm to 100 mm), has boosted power from 12 hp to

15.5 hp.

As a result, it became an engine that produces high torque even

at a low rpm.

In actual fields and rice paddies, lighter and smaller engines are preferred over larger and heavier engines in this class. Furthermore, the work requires high torque at low speeds. A light and powerful engine, an engine that doesn't break down, Kubota's horizontal diesel engine is an engine that doesn't compromise on the demands of the field.

A Horizontal Diesel Development Group Filled with Pioneering Spirit

The horizontal diesel engine development team created a new combustion chamber ahead of Kubota's overseas expansion, and it is said that they have a free and broad-minded attitude and a strong enterprising spirit.

They started using CAD for engine development and design earlier than any other department. Although this is partly because single-cylinder engines are easier to adapt to CAD, it is also because they have taken on the role of driving Kubota's engine business.

The horizontal diesel engine has been used not only for agricultural machinery, but also as an engine for pumps used to extract crude oil.

Again, Kubota's engineers actually visited the oil fields in Yemen and Egypt, as well as cold regions in winter, such as Siberia and North Dakota in the U.S., and expanded the range of applications for horizontal diesel engines.

Kubota's early oil engines were originally horizontal. Later, with Kubota's independent development of the horizontal diesel engine during the transition to diesel engines, this small, lightweight, yet powerful engine expanded its uses in the agricultural and industrial fields, and became a pioneer in Kubota's overseas expansion.

In the 100-year history of Kubota engines, the horizontal diesel engine has not come in just one form. It has always been a vessel for taking on new challenges, and a place to communicate with customers. The results of these repeated attempts have brought about the evolution of Kubota's engine business. Kubota's horizontal diesel engine is a symbol of the new value Kubota offered in agricultural and industrial machinery around the world.