Bajaj Auto

Bajaj Auto is an Indian manufacturer of two-wheeled and three-wheeled vehicles that was founded in 1926.

It is the core company of the Bajaj group, founded by Jamnalal Bajaj. They mainly manufacture scooters, motorcycles, and three-wheeled vehicles.

It is also the world's largest manufacturer of three-wheeled vehicles. Furthermore, when it comes to motorcycle sales, it is the fourth largest manufacturer in the world (in 2020), after Honda (Japan) in first place, Yamaha (Japan) in second place, and Hero MotoCorp (India) in third place, and ahead of Harley Davidson and BMW.

In addition to this, Bajaj Auto is the largest shareholder of the British motorcycle manufacturer KTM, and has entered into a global partnership with Triumph Motorcycles (also British) in 2020. They have attracted worldwide attention and are expected to make even greater strides in the motorcycle industry.

Although the three-wheeled vehicles in Thailand and other Southeast Asian countries known as "tuk-tuks" are well-known, the three-wheeled vehicles manufactured by Bajaj are called "auto rickshaws," and are completely different from tuk-tuks.

The main export destinations for three-wheeled vehicles are Sri Lanka, Mexico, Bangladesh, Colombia, Peru, Egypt, Iran, and Indonesia. They have a sales network in 50 countries around the world.

There are two types of auto rickshaws from Bajaj, passenger types and goods carrier types.

So, what is the relationship between this cute looking auto rickshaw and the Kubota engine? Let us unravel the history.

Heartfelt Appeal from Bajaj Auto

Until around the 1990s, Bajaj Auto's three-wheeled vehicles were equipped with an air-cooled two-stroke cycle engine that was designed for motorcycles.

However, it was difficult to adapt these engines to the emission regulations that were soon to be implemented, and the company had to improve its own engine manufacturing technology. I believe that Bajaj Auto must have felt a great sense of impending peril, as it would be difficult to meet emission regulations with things as they were.

So, Bajaj Auto looked for an engine manufacturer that could provide its technology. After comparing engines from various manufacturers, the company decided on Kubota OC engines because of their ability to meet emission regulations, improve fuel efficiency, and operate quietly.

In 1993, Kubota received a direct request from the top management of Bajaj Auto's engineering department, asking to use the OC95 engine technology.

The Kubota OC (Oil Cooled) Engines that Caught the Eye of Bajaj Auto

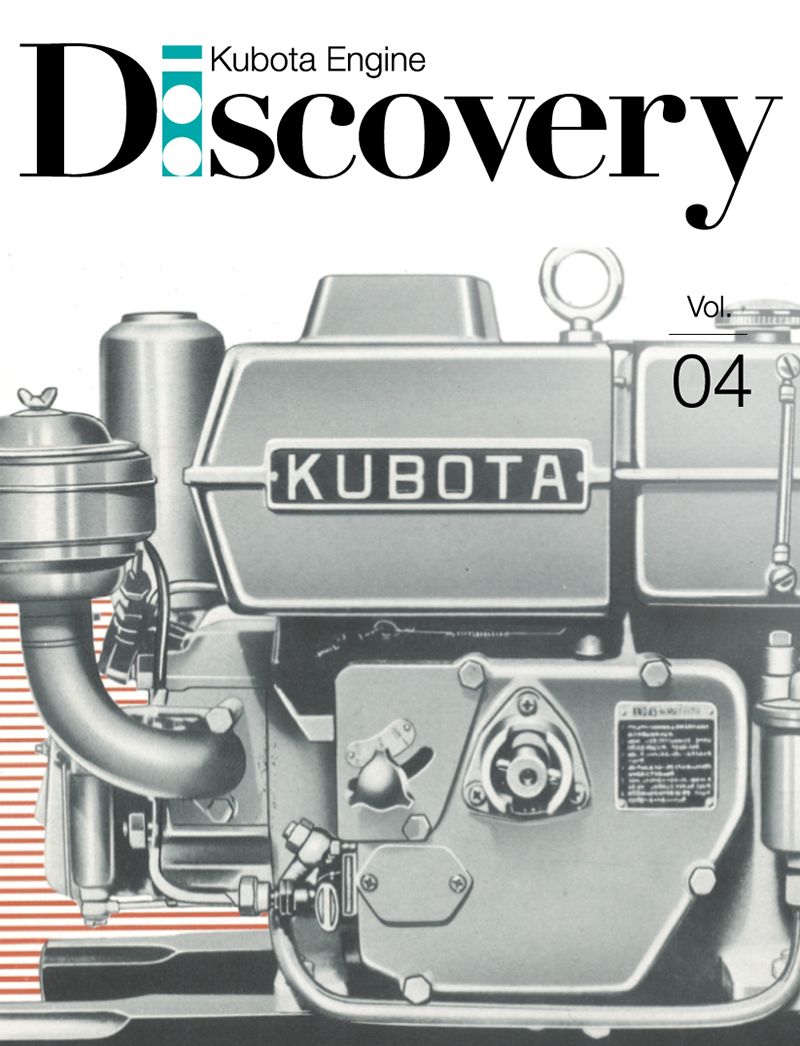

Kubota OC engines, for which the world's largest three-wheeled vehicle manufacturer, Bajaj Auto, sent a heartfelt appeal, are small diesel engines developed in 1988 that use an oil cooling method rather than being air-cooled or water-cooled.

The ACTV system single-cylinder diesel engine is equipped with Kubota's proprietary TVCS (swirl-chamber indirect-injection) combustion chamber. In this revolutionary system, oil is circulated around the combustion chamber, with the high heat generated during combustion being absorbed by the oil and then dissipated by an oil cooler, after which the cooled oil is returned to the crankcase. This allows the TVCS combustion system to produce less noise and less unpleasant odors.

Furthermore, the dual layer structure created by the oil layer around the cylinder head absorbs combustion noise. External emission noise is reduced, and in synergy with the TVCS combustion system, it is possible to reduce noise compared to air-cooled diesel engines.

Bajaj Auto specifically requested this engine because Kubota's OC95 was suitable for adapting to India's emissions regulations, as well as for its fuel economy performance.

In addition, as three-wheeled vehicles are also used as taxis, quietness was also considered to be important, which is why IDI was preferred instead of direct injection.

Technology Grant, not Original Equipment Manufacturer

Bajaj Auto has two types of three-wheeled vehicles, Passenger and Goods Carrier types. They also offer a wide range of products powered by gasoline, gas, diesel, and electricity.

Kubota and Bajaj Auto have had a "Technology License Agreement" since 1997 for development of a diesel engine to be used in these three-wheeled vehicles.

The engines themselves are manufactured in-house by Bajaj Auto instead of by Kubota, so Kubota began by providing the designs and blueprints for installing the OC95 in three-wheeled vehicles, as well as providing support for a mass production system.

Additionally, in order to comply with the Indian emissions regulations that were implemented over stages from 2000, the technology provision agreement between Kubota and Bajaj Auto lasted until March 2013, a total of 15 and a half years.

Part 1 (December 1997 to September 2004)

OC95 engine design and manufacturing support

Part 2 (October 2004 to March 2008)

Compliance with BS2 (Bharat Stage II), the second level of

India's three-wheeled vehicle emissions regulations

Part 3 (April 2008 to March 2013)

Compliance with BS3 (Bharat Stage III), the third level of

India's three-wheeled vehicle emissions regulations

Generator and Pump Engines Customized for Three-wheeled Vehicles

The mission of the technology license between Bajaj Auto and Kubota, which began in 1997, was "to manufacture engines in-house based on OC95 technology for use in three-wheeled vehicles."

Kubota's OC95 engine was used for applications such as generators, pumps, backhoes, and was not an automotive engine designed for driving vehicles.

To enable its use Bajaj Auto's three-wheeled vehicles, it was necessary to work out the mounting method and other details for direct connection with the transmission.

In addition, as three-wheeled vehicles are vulnerable to tipping over, specification changes, such as improvements to the blazer mechanism, were necessary to safely stop the engine if the vehicle tipped over.

Then, based on the designs made by Kubota of the "OC95 Engine for Bajaj, "Kubota provided support to Bajaj Auto so that it could manufacture the engine at its own plant. We provided support for a mass production system by implementing Kubota's expertise in production technology into Bajaj Auto's manufacturing department in Aurangabad.

Engine tuning was also performed, including the creation of engine performance curves and the assessment of parts related to manufacturing. We also conducted numerous in-depth exchanges, such as inviting key personnel from Bajaj's manufacturing department to the Rinkai Plant for training and having Kubota engineers provide on-site guidance at the Aurangabad plant.

Despite cultural differences between India and Japan, thanks to the technology license of Kubota, Bajaj's OC95-equipped three-wheeled vehicles were completed, highly praised by the market, and enjoyed excellent sales.

The Struggle with Emission Regulations that Differ from Those for Industrial Machinery Engines

After the first contract (December 1997 to September 2004), the technology provisioning relationship between Kubota and Bajaj continued.

The second (October 2004 to March 2008) and third (April 2008 to March 2013) contracts were primarily for complying with India's increasingly stricter emission regulations.

The Bharat Stage Emission Standards (BSES), first introduced by the Indian government in 2000, were regulations to control the emission of air pollutants from internal combustion engines and spark ignition engines, including automobiles.

Although the content and timing of enacted standards differed depending on the vehicle, regulatory compliance from BS1 (Bharat Stage I) to BS3 (Bharat Stage III) was covered for the period of the technology license agreement between Kubota and Bajaj Auto.

Kubota was the first company in the world to comply with the U.S. California Air Resources Board (CARB) Tier 1 regulations for engines under 25 horsepower in 1993. Since then, Kubota has continued to lead the industry in meeting off-road emission regulations implemented in Europe, the U.S., and Japan.

Although it may seem easy to apply that experience to Indian on-road emission regulations, there are several conditions for three-wheeled vehicles that are different from those for industrial machinery, requiring Kubota to take a different approach than its experiences in the past.

Emission regulations for three-wheeled vehicles demand "emissions compliance with the engine installed in the vehicle." Improvements must be made to the design of mechanisms used by the engine itself, as well as to the vehicle as a whole in order to meet emission regulation values.

To achieve this, it was necessary to change how engine bench testing had been conducted in the past.

The engine has been tuned on differently than usual at Kubota's engine test bench in Japan. This is by using a data established with the driving simulation of the engine as if it were installed in a vehicle. Then the engine is dispatched from Japan to India, the actual exhaust gas emissions are tested in India with the engine installed in the vehicle. Because this measuring equipment is only approved by accredited organizations in India, Kubota engineers had to be on site to conduct the test.

Furthermore, the testing process was also apparently different and quite difficult.

Bajaj's three-wheeled vehicles only have manual transmissions. Because an automatic transmission is not used, bench test results would change depending on the driver, which caused a great deal of variation and made testing a challenge. In addition, because the operation of the three-wheeled vehicle's transmission is unique, if the timing of the gear change is off even slightly, the speed will not increase, making it even more difficult to perform testing smoothly.

Therefore, despite receiving good results in the prior simulations in Japan, there were many cases in which the local tests did not produce the anticipated results.

India’s BS3 Emission Regulations, Considered to be the Harshest

In order to comply with Tier III of the emission regulations for

three-wheeled vehicles, known as BS3 (Bharat Stage III), it was

necessary to meet requirements that were far stricter than

anything seen in the past.

BS3 was extremely strict, only allowing half the exhaust gas

components (NOx+HC and PM) as BS2, while also requiring the

vehicle to weigh more. Meeting all of these requirements was

very difficult compared to the regulations in other parts of the

world at the time.

First, the exhaust gas components "NOx+HC" and "PM" have a "trade-off" relationship in which reducing one increases the other, making it difficult to reduce both at the same time.

Also, increasing the weight of the vehicle means increasing the load on the engine, which in turn means increasing the volume of exhaust gas emissions.

Furthermore, when measuring exhaust gas, it was required to do so from a cold start (which was rare in the world at that time). If the measurements are taken after warming up, exhaust gases are less likely to be emitted, but if the measurements are taken after sitting for an entire day, it is amount that the volume of exhaust gases will be higher.

Complying with these regulations, which were some of the strictest ever, was one of the most difficult tasks to date, and even Kubota's own engineers had to admit that the "prospects were bleak."

This was a very difficult challenge even for Kubota.

Despite the uncertainty of whether they could achieve it within the time limit, they were determined to do it for Bajaj Auto.

Each and Every Possibility, Addressed with Care

This was not the first time that Kubota had dealt with automotive (on-road) emission regulations.

This was the second example after the French passenger microcar from Aixam. However, Aixam's vehicles were subject to regulations for passenger car types used under light loads, while Bajaj Auto's three-wheeled vehicles required engine tuning for use under full load.

The only way was to repeat a process of trial-and-error with our own unique approach. After considering more than 30 development points to help the three-wheeled vehicle comply with BS3, engineers repeatedly designed/ prototyped the engine in Japan and tested it on-site.

They said the difference between the world of the exhaust gas they envisioned by steady mode measurements and the world of combustion during by the transient driving was unimaginable. Of the 30 points, 14 or 15 points ended up being actually used for development.

To add to this, India's official emissions testing agency is located at an altitude of about 620 meters above sea level. Development was an exploration that involved trying every possible means to find a way to bridge the gap of developing the engine in Japan, at zero meters above sea level.

With vehicle-based emission regulations, there is no way to know until you actually try it. Even with failures, the goal is always in sight! With this in mind, they traveled back and forth between Japan and India, carefully addressing each challenge one by one.

There were 10 members in the horizontal diesel department at that time. These 10 members shared information and came up with ideas together to advance the development. Furthermore, it is amazing that during this time, the department was not only working on BS3 in India, but also on the separate development issues in Japan, Thailand, and Indonesia simultaneously. (Still, it seems that the tuning for India was the hardest.)

The trial and error continued, but the deadline loomed on the horizon. Bajaj laid out several phased targets to meet before the deadline, so development and testing proceeded while meeting those target numbers.

Finally, the final gate was to have "10 mass-produced engines clear the regulation values of NOx+HC 85% or below and PM 75% or below." As all concerned watched while holding their breath, all 10 cars cleared this final hurdle by a comfortable margin. It was then that the technical executives of Bajaj Auto said "Excellent!" in praise.

Somewhere in the World Today

After clearing BS3, the contract between Kubota and Bajaj Auto ended in March of 2013, but the engines carrying the DNA of Kubota's technology are still in use today.

Indian business culture is said to be different from that of Japan. Bajaj Auto reportedly had a Western-style of business that was dry, sophisticated, and stylish. In the technical divisions there is a thorough Western-style division of labor, which differs from the culture in Japan. However, the engineers were able to build a relationship with each other through personal discussions, nurturing a relationship of trust that transcended business.

Environmental regulations demand results measured against strict numbers.

However, behind those numbers are not dramatic innovations or solutions, but rather a story of continuous effort, endless trial and error, earnest communication, and mutual trust between Japan and India, which cannot be expressed in numbers.

Bajaj Auto's three-wheeled vehicles (diesel versions), which inherited Kubota's legacy, have sold more than a million units and are no doubt still carrying people and goods and delivering smiles to in cities and towns around the world today.